A family Company

from the Beginning

Mining Perlite together since 1958

Our Story

Pronounced “PAW-rock”

This is the correct pronunciation of our name, coming from our Native Indian roots. Piute Indians were native to our area and we have a lot of water in our beautiful county. We believe “pah” meant water so we have “Panaca Spring”, Pahranagat Valley and the Pahroc Mountain Range. Perlite rock is volcanic glass that has water trapped inside of it—so it is water rock or Pahroc.

Mackie Perlite Mine

Our dear Grandpa, Bob Wilkin began mining this exceptionally expansive perlite in 1958 for the Paramount Perlite Co., makers of the “Sponge Rok” perlite brand. Today, the ore continues to be mined and kilned by his great-grandchildren who take pride carrying on in this family tradition and producing the largest expanded perlite in the world.

Mackie Perlite Mine

Our dear Grandpa, Bob Wilkin began mining this exceptionally expansive perlite in 1958 for the Paramount Perlite Co., makers of the “Sponge Rok” perlite brand. Today, the ore continues to be mined and kilned by his great-grandsons who take pride carrying on in this family tradition and producing the largest expanded perlite in the world.

Professional Growers

Professional growers require high quality and consistent sized perlite to achieve consistent and beautiful results. Pahroc Giant Exxxpanded Perlite has served professionals with quality product for decades.

Why Pahroc

Homegrown Product

About 25-30% of crude perlite ore is imported from Greece to the U.S. 100% of our perlite is mined and kilned in Nevada; supporting a lot of good families and contributing to our economy.

Environmentally Conscious Family Company

Our perlite mine is located in an economically depressed, remote area in Nevada. The environmental impact is not severe. The mineral fines, overburden, and reject ore are used to reclaim the mined-out areas, leaving little waste remains. Airborne dust is captured by baghouses and tilled into local farms, improving moisture retention of the soil and reducing water consumption. Virtually no runoff contributes to water pollution.

Highest Quality

Our priority has always been to produce the cleanest, largest, uniformly sized perlite product in the world. Perlite customers do NOT want a bag of dust! Perlite dust just holds water similar to what peat, coir or your vermiculite is doing for you already. Consistent, reliably sized perlite allows the grower to custom design his grow media and get consistent results.

Go to Source for Biggest Sizes

Our specialty is big, large, chunky, beautiful, clean perlite. Competitors claim to produce the large particles loved by orchid growers or the hydroponics industry but don’t be fooled, their “Coarse” perlite doesn’t compare to PAHROC GIANT. (FYI: if you do happen to have a bag of dust, it does work great in cleaning up oil spills in the driveway or starting cuttings :))

How is Pahroc GIANT Exxxpanded Perlite Made?

Step 1

Mine the Mineral

Step 2

Crush the Materials

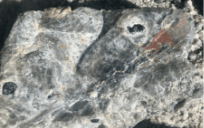

This is a chunk of crude perlite ore prior to being crushed containing a couple of pieces of obsidian (apache tears) embedded in it as well as pink and yellow rhyolite streaks. Obsidian is basically baby perlite that wasn’t exposed to water when the volcanic flow was moving and it will not expand. When we come upon pockets of obsidian, we remove as much as possible by hand and crush the remaining perlite ore to the required size.

Step 3

Expand and Size

The crude, crushed perlite ore is transported to a calcination plant where it is put into a 2000 degree F furnace. The trapped water in the perlite turns to steam and thus pops or plumps the perlite into ultra, lightweight particles up to 20 times its original volume.

Topsoil and organic matter are removed from the surface of the perlite deposit and stockpiled along the edge of the operation in order to be used in reestablishing vegetation in post mining reclamation. Crude ore perlite is dug from the site by dozer and loaded onto trucks to be crushed at local crushing plant. Whenever possible, Wilkin Mining & Trucking, Inc. conducts land reclamation concurrently with the mining operations. Reclamation consists of contouring the land and seeding to reestablish the flora. We seek to meet or surpass all environmental regulations and guidelines

Perlite mining results in minimal disturbance to the land and supports jobs in agriculture, natural resources, transportation, engineering, packaging, distribution, and many more.